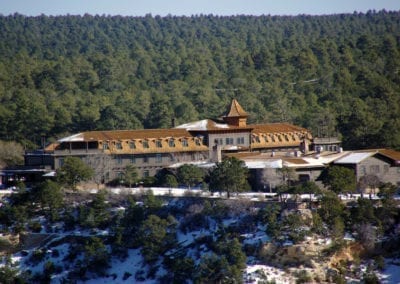

The Downtown Connection Center (DCC) is a state-of-the-art, 20,938-square-foot transit hub and civic space located in downtown Flagstaff near Milton Avenue and Phoenix Avenue, adjacent to the BNSF rail line. The project is part of the “Downtown Mile” suite of infrastructure improvements and is designed as an all-electric facility featuring Cross-Laminated Timber (CLT)/mass timber construction, in-floor heating, a chilled beam system, and integrated photovoltaics. The first floor houses a community room, lobby, and restrooms for bus patrons, while the second floor includes office and support spaces for Mountain Line staff.

Preconstruction Services

- Delivered multiple Guaranteed Maximum Price (GMP) packages to accelerate the fast-track schedule, including:

- Achieved significant savings in accepted value engineering without compromising sustainability features.

FTA grant funding component included BABA compliance requirements, making this the first American-made mass timber building in Arizona.

Construction Innovations

- Managed delegated design for mass timber in collaboration with Timberlab, including structural analysis and streamlined constructibility confirmations.

- Created a comprehensive BIM model for live 3D design reviews, enabling clash avoidance and stakeholder collaboration.

- Ensured segregation of construction activities from active transit operations with temporary driver break stations and daily coordination with Mountain Line.

Sustainability and Certifications

- First building certified “Gold” under the Coconino County Commercial Sustainability Standards.

- Served as the model project for defining the standard between Coconino County, HDR, and Loven Contracting’s preconstruction team.

Public Art Integration

- Partnered with the City of Flagstaff Beautification, Arts, and Sciences Department to integrate public art features, including art glass and sculptural elements. When complete, this will be the largest public art project for the City of Flagstaff’s growing arts program.

Site Challenges and Solutions

- Mitigated challenges posed by snow events, the proximity to the BNSF rail line, and the Rio de Flag flood zone.

- Collaborated with the City of Flagstaff, APS, Unisource, ADOT, the Army Corps of Engineers, and BNSF for utilities, inspections, and flood mitigation.

Addressed cold weather issues by manually removing snow and accelerating mass timber installation.

Judges Reveal Finalists for Southwest’s Project of the Year: Talk of the Rockies | Engineering News-Record

Best Airport/Transit Project of the Year: Talk of the Rockies | Engineering News-Record

Bus Facility Brings Mass Timber to Northern Arizona, By Scott Blair, Editor-in-Chief

Bus Facility Brings Mass Timber to Northern Arizona Video: ENR Videos | Engineering News-Record